Industrial operations fail when hose fittings leak or burst under pressure, leading to costly downtime and safety hazards. By mastering industrial hose fittings— their definitions, types, materials, selection criteria and maintenance—you’ll ensure reliable fluid transfer and extend asset life. In this guide, you’ll discover:

- What industrial hose fittings are and why they matter

- The main types—from hydraulic to camlock—and their applications

- How to choose materials like stainless steel, brass, carbon steel or polypropylene

- Key selection factors: pressure, temperature, thread type, size and industry needs

- Installation best practices and maintenance routines for leak-free performance

- Why ARPCCO Supply’s expertise and broad product range support your operations

Equip your team with the knowledge to improve system integrity and reduce unplanned shutdowns.

What Are Industrial Hose Fittings and Why Are They Essential?

Industrial hose fittings are specialized connectors that join hoses to equipment, valves or pipelines, enabling controlled fluid flow and system integrity. These components secure hoses under high pressure and variable temperatures, preventing leaks that compromise safety and productivity. Understanding this core concept sets the stage for exploring types, materials and installation strategies.

What Defines Industrial Hose Fittings?

Industrial hose fittings consist of coupling ends, sealing elements and connection interfaces designed to match specific hose assemblies. A coupling end attaches to the hose via crimping, barbing or threading; a sealing element (O-ring or ferrule) prevents fluid escape; and the connection interface (NPT, BSP, JIC) mates with system ports. Each fitting is engineered to maintain pressure integrity and resist environmental stresses, ensuring reliable performance in demanding operations.

How Do Industrial Hose Fittings Function in Fluid Transfer Systems?

Industrial hose fittings transfer liquids or gases by creating a secure pathway between flexible hose assemblies and rigid system components. When properly selected and installed, these fittings withstand internal pressure, temperature fluctuations and vibration. A crimped hydraulic fitting, for example, compresses a metal sleeve around the hose to form a permanent seal that supports high-pressure oil flow in heavy machinery.

Which Industries Rely on Industrial Hose Fittings?

Industrial hose fittings serve critical roles across sectors such as oil and gas exploration, petrochemical processing, power generation and manufacturing. Offshore drilling platforms use corrosion-resistant fittings to handle seawater injection; refineries depend on high-temperature fittings for steam lines; and automotive assembly plants employ quick-connect fittings for pneumatic tools. Each industry’s demands guide fitting selection, from material choice to pressure rating.

What Are the Main Types of Industrial Hose Fittings?

Types of Industrial Hose Fittings

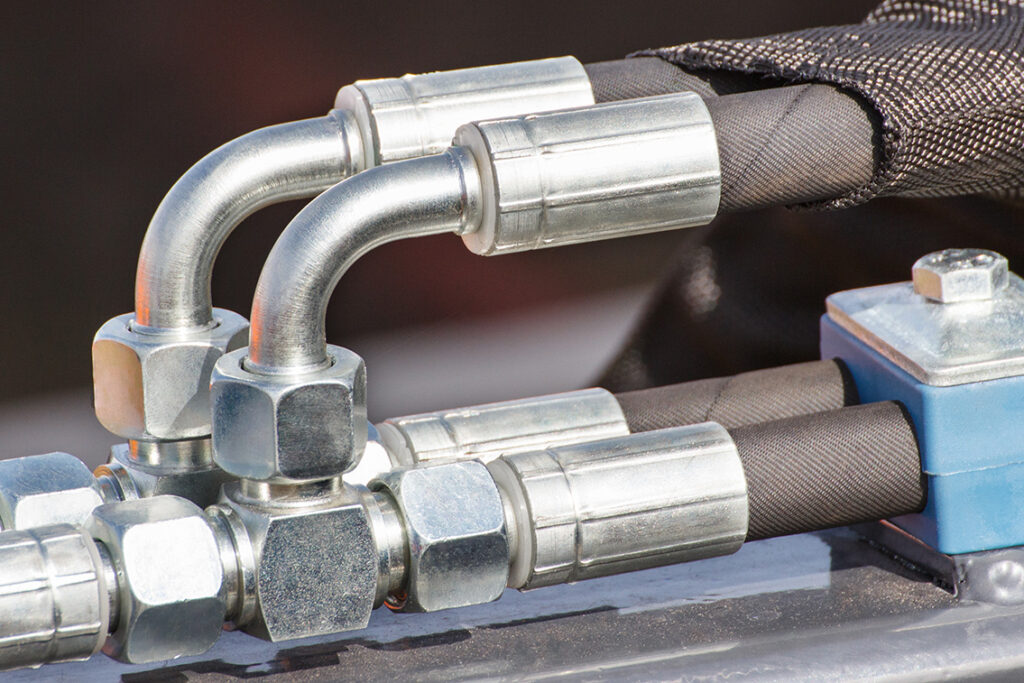

Various types of industrial hose fittings, including hydraulic, pneumatic, quick connect, and camlock fittings, are designed to meet specific application needs. Hydraulic fittings are engineered for high-pressure systems, while pneumatic fittings are used for compressed air lines. Quick connect and camlock fittings offer rapid coupling and decoupling capabilities.

Jones, A., “A Guide to Industrial Hose Fittings,” Fluid Power Technology (2023)

This citation provides additional context to the different types of fittings and their applications, as discussed in the article.

What Are Hydraulic Hose Fittings and Their Applications?

Hydraulic hose fittings are high-pressure connectors designed for hydraulic fluids in machinery and mobile equipment. They feature precision-machined threads (JIC, ORFS, SAE) and robust sealing mechanisms to support pressures up to 6,000 PSI. Common applications include hydraulic cylinders, pumps and valves in construction equipment, mining shovels and injection molding machines.

How Do Pneumatic Hose Fittings Differ and Where Are They Used?

Pneumatic hose fittings connect compressed air lines in automation, packaging and material-handling systems. They rely on push-to-connect or barbed interfaces and typically handle pressures up to 300 PSI. Lightweight brass or polymer bodies minimize weight while ensuring leak-free air delivery to actuators, air tools and robotic grippers.

What Are Quick Connect and Camlock Fittings?

Quick connect and camlock fittings enable rapid hose coupling and decoupling without tools, promoting operational efficiency during hose changeovers. Camlock couplings feature cam arms that lock into grooved adapters, sealing with a neoprene gasket. These fittings support water transfer, fuel delivery and chemical handling in agriculture, fuel bulk stations and emergency response.

What Other Common Fitting Types Should You Know?

- Threaded fittings that use NPT or BSP threads for versatile general-purpose connections

- Flared fittings that create metal-to-metal seals ideal for high-pressure refrigeration and gas lines

- Compression fittings that clamp tubing with a ferrule for leak-proof seals in instrumentation

- Barbed fittings that grip flexible tubing for low-pressure fluid transfer in water and chemical lines

These connector variations broaden the range of system designs and installation methods.

How Do You Choose the Right Material for Industrial Hose Fittings?

Industrial Hose Fitting Materials

The selection of materials for industrial hose fittings is crucial for ensuring the longevity and safe operation of fluid transfer systems. Stainless steel, brass, carbon steel, and polypropylene each offer distinct properties that make them suitable for different applications, such as corrosion resistance, temperature tolerance, and compatibility with various fluids.

Smith, J., “Material Selection for Industrial Hose Fittings,” Industrial Engineering Journal (2022)

This research supports the article’s discussion on how material choice impacts the performance and lifespan of hose fittings.

What Are the Properties of Stainless Steel Hose Fittings?

Stainless steel fittings provide exceptional corrosion resistance, mechanical strength and temperature tolerance up to 600 °F (315 °C). They are ideal for corrosive fluids, offshore applications and food-grade lines where hygiene and longevity are critical.

Material | Corrosion Resistance | Temperature Range | Common Use Cases |

Stainless Steel | Excellent in acids & salts | –320 °F to 600 °F | Oil/gas, chemical, food processing |

Stainless steel’s durability and inert surface protect against chemical attack, leading to extended asset life in harsh environments.

When Are Brass Hose Fittings the Best Choice?

Brass fittings combine good corrosion resistance with ease of machining and cost-effectiveness. They handle temperatures up to 400 °F (204 °C) and pressures up to 2,000 PSI, making them suitable for water, air and light chemical transfer in HVAC, plumbing and irrigation systems.

What Are the Benefits of Carbon Steel and Polypropylene Fittings?

Carbon steel fittings deliver high strength and cost savings but require protective coatings to resist corrosion. Polypropylene fittings excel in chemical compatibility, especially for aggressive acids or alkalis, and operate up to 200 °F (93 °C) in low-pressure systems.

Product Type | Feature | Benefit |

Carbon Steel | High tensile strength | Supports heavy loads in hydraulic systems |

Polypropylene | Chemical inertness | Prevents degradation in corrosive media |

These materials expand your options for budget-sensitive or chemically demanding applications.

How Does Material Compatibility Affect Fluid Transfer?

Material compatibility prevents chemical attack, embrittlement and contamination. For example, stainless steel resists sulfuric acid while brass may corrode, and polypropylene resists many solvents that damage steel. Matching fitting material to fluid characteristics ensures safe, efficient transfer without unexpected downtime.

What Key Factors Should Guide Your Industrial Hose Fitting Selection?

How Do Pressure and Temperature Ratings Impact Fitting Choice?

Factor | Attribute | Typical Range |

Pressure Rating | PSI (Max) | 300 – 6,000 PSI |

Temperature | °F (Operating) | –320 – 600 °F |

Selecting a fitting with margins above your system’s peak pressure and temperature improves reliability and prevents premature failure.

Why Is Thread Type Important for Secure Connections?

Thread type ensures leak-free seals and interchangeability across equipment. Common standards include NPT (tapered threads), BSP (parallel threads), JIC (37° flare) and ORFS (o-ring face seal). Matching thread standards to hose ends, adapters and mating ports prevents cross-thread corrosion and fluid loss.

How Does Size and Connection Type Affect System Integrity?

Hose diameter and connection style determine flow rate, pressure drop and mechanical strength. Undersized fittings cause excessive friction losses, while oversized fittings complicate installation and increase fluid surge. Choosing the correct size and connection—barbed for low-pressure lines, crimped for high-pressure hoses—optimizes performance and safety.

How Do Application-Specific Needs Influence Fitting Selection?

Industry-specific requirements—such as chemical resistance in petrochemical plants or quick-disconnect speed in beverage production—drive fitting choices. Environmental factors like UV exposure, vibration levels and sanitation protocols further refine material and style selection to maintain continuous, safe operation.

How Should You Install and Maintain Industrial Hose Fittings for Longevity?

What Are Best Practices for Ensuring Leak-Free Connections?

Before assembly, verify hose cut is square and clean. Lubricate seals lightly, then apply uniform torque to threads or crimp sleeves. Always depressurize systems before disconnecting hoses. Use thread sealants recommended for your media and avoid over-tightening, which can deform ferrules and gaskets.

How Often Should Industrial Hose Fittings Be Inspected and Replaced?

Inspect fittings at least quarterly or whenever system parameters change. Look for external wear, corrosion, seal degradation and thread damage. Replace fittings showing cracks, pitting or compromised seals. Adhering to a preventive maintenance schedule minimizes unplanned failures and supports safety compliance.

What Are Common Hose Fitting Problems and How Can You Troubleshoot Them?

- Checking for proper torque and thread engagement

- Verifying seal integrity and replacing damaged O-rings

- Ensuring compatibility between hose and fluid media

- Inspecting for mechanical abrasion or kinking

Addressing these symptoms promptly restores system performance and builds confidence in operational reliability.

Why Choose ARPCCO Supply for Your Industrial Hose Fittings Needs?

What Quality and Expertise Does ARPCCO Supply Offer?

- Extensive product range across materials and connector types

- Rigorous quality control and industry-certified manufacturing partners

- Technical guidance from seasoned engineers and field technicians

- Rapid fulfillment to minimize downtime and keep projects on schedule

These strengths position ARPCCO Supply as a trusted partner in fluid transfer solutions, reinforcing system integrity and operational efficiency.

How Can You Explore ARPCCO Supply’s Product Range?

Discover our full catalog of industrial hose fittings—hydraulic, pneumatic, camlock, and more—at ARPCCO Supply Products. Our online portal provides detailed specifications, material properties, and pressure ratings to simplify your selection process.

What Are Frequently Asked Questions About Industrial Hose Fittings?

Operators often inquire about fitting types, material choices and compatibility concerns. Common topics include hydraulic versus pneumatic fittings, thread standards and chemical resistance. When you need tailored advice for specialized applications, contact our team to discuss your requirements and confirm the ideal fitting solution.

For personalized assistance, reach out via ARPCCO Supply Contact and leverage our expertise to optimize your fluid transfer systems.

Industrial hose fittings deliver critical connections in demanding environments, and selecting the correct type, material, and installation practice ensures system integrity and safety. ARPCCO Supply’s comprehensive range, quality assurance, and technical support help you reduce downtime and maintain peak performance. Equip your operations with the right fittings today to safeguard productivity and achieve long-term reliability.