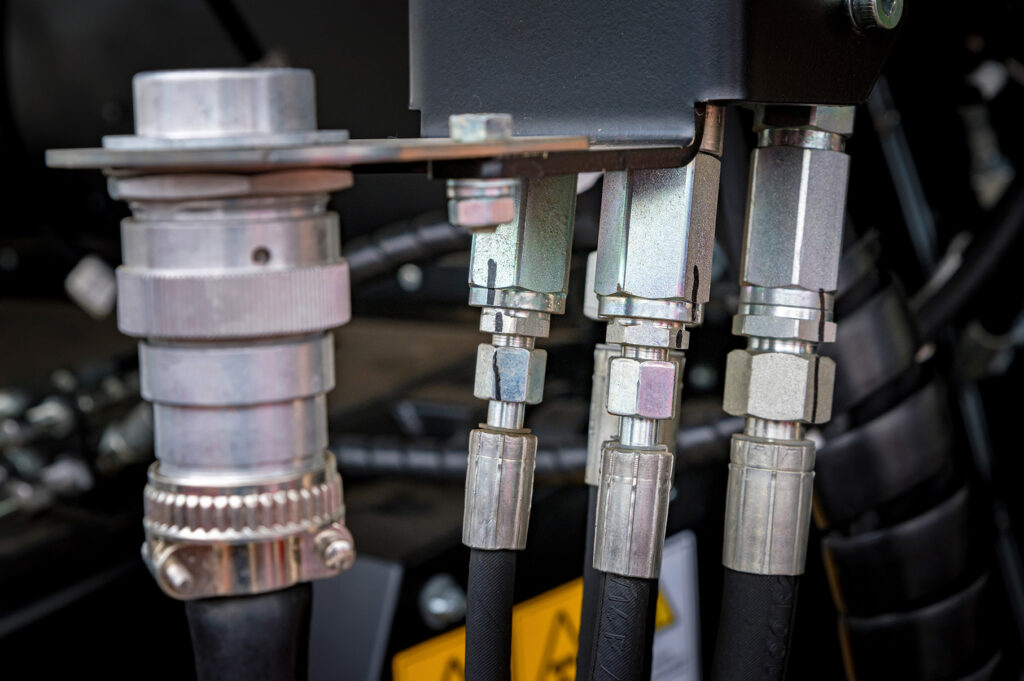

Steel hydraulic fittings are engineered connectors that join sections of hydraulic piping or tubing, ensuring secure, leak-free connections under high pressure. They transfer hydraulic fluid between components while resisting aggressive conditions such as high fluid pressures and chemical exposure. Fabricated from carbon steel, stainless steel, or alloy materials, these fittings deliver consistent performance, durability, and precision. Industries such as heavy machinery, construction, aerospace, and petroleum demand fittings that comply with strict performance and safety standards set by organizations like ANSI and BSP.

What Defines a Steel Hydraulic Fitting?

A steel hydraulic fitting is defined by its robust material composition, precise design, and high performance under extreme pressure and corrosive conditions. Typically made from high-grade metal, these fittings include adapters, elbows, tees, and couplings that form secure, leak-proof joints in a hydraulic circuit. Their design accommodates specific hydraulic fluids, maintains system integrity during temperature fluctuations, and resists wear through precision machining and welding.

How Do Steel Hydraulic Fittings Differ From Other Materials?

Unlike brass, aluminum, or plastic fittings, steel hydraulic fittings are designed for high-pressure and high-temperature environments. Carbon and stainless steel variants offer superior strength, excellent durability, and enhanced corrosion resistance. While brass may suit low-pressure applications, steel fittings can handle far greater stress. The alloy composition in some steel fittings further improves mechanical properties, making them indispensable in environments where failure risks are high.

What Industries Rely on Steel Hydraulic Fittings?

Many industries depend on steel hydraulic fittings due to their robust performance. The petroleum and petrochemical sectors use them where high pressures, extreme temperatures, and corrosive fluids are common. In construction and mining, reliable fittings are crucial for hydraulic machinery. Aerospace and defense require precision fittings in avionics and propulsion systems, while manufacturing relies on them for continuous production line efficiency. Essentially, any industrial setting that demands reliable hydraulic function benefits from these fittings.

Which Types of Steel Hydraulic Fittings Are Available?

Steel hydraulic fittings come in various types, each serving a specific role in a hydraulic system. Common types include adapters, elbows, tees, and couplings, designed to suit different configurations and pressure levels. Additionally, choices between carbon steel and stainless steel adapt to environmental needs. Industry standards specify dimensions, tolerances, and connection methods to ensure safety and reliability. This section provides an overview of the common fitting types and the guidelines that inform their design and use.

What Are the Common Types: Adapters, Elbows, Tees, and Couplings?

Adapters connect pipes with different thread types or sizes, while elbows enable directional changes in piping layouts. Tees allow branch connections to distribute fluids to multiple components. Couplings securely join hoses, tubes, or pipes. All these fittings feature engineered threads or face seals to prevent leaks and maintain pressure. For instance, a well-designed elbow can reduce fluid turbulence compared to a standard design, improving overall system efficiency.

How Do Stainless Steel Fittings Compare to Carbon Steel Options?

Stainless steel fittings are preferred for applications involving chemically aggressive fluids or humid, saline environments because of their superior corrosion resistance. Carbon steel fittings can be less expensive and offer excellent strength for high-pressure use but may require more frequent replacement. When longevity and resistance to oxidation are critical—such as in food processing or marine applications—stainless steel is often the material of choice, despite its higher upfront cost.

What Industry Standards Apply to Steel Hydraulic Fittings?

Steel hydraulic fittings are manufactured to meet high industry standards such as those defined by ANSI, ISO, and BSP. These standards regulate thread types, pressure ratings, and tolerances to ensure that fittings from different manufacturers work interchangeably without compromising safety. Certifications from recognized bodies also provide assurance of product quality and reliability, safeguarding both equipment and personnel.

How to Choose the Best Steel Hydraulic Fittings for Your Application?

Selecting the best steel hydraulic fittings involves evaluating pressure capacity, hydraulic fluid compatibility, environmental factors, and connection types. Proper matching of these factors ensures safe, efficient system operation. This section guides engineers and procurement specialists through key considerations—ranging from system specifications to potential customization needs—to enhance overall system reliability and reduce maintenance challenges.

What Factors Affect the Selection of Steel Hydraulic Fittings?

Key selection factors include the system’s working pressure, the type of hydraulic fluid, operating temperatures, and potential exposure to corrosive agents. Compatibility with connected pipes, hoses, and valves is also critical. Decisions between carbon steel and stainless steel depend on the operating environment and system lifespan. Other considerations such as vibration, application cycle frequency, and future scalability also influence the choice. For example, marine systems often require the corrosion resistance of stainless steel, whereas mining systems may prioritize carbon steel’s strength.

How to Match Fittings to Hydraulic System Requirements?

Matching fittings to a hydraulic system begins with determining crucial specifications like maximum pressure and fluid type. The fitting’s thread type, dimensions, and connection style—whether compression, threaded, or quick-connect—must align with the system’s layout. Detailed specification sheets, blueprints, and professional assessments (or simulations) are invaluable in ensuring compatibility. Correct matching minimizes turbulence and energy loss by ensuring that the internal diameters and connection styles are properly aligned.

When Is Custom Steel Hydraulic Fitting Design Necessary?

Custom fittings are necessary when standard products cannot meet unique system requirements such as non-standard piping sizes, specialized fluids, or unusual layouts. In innovative or high-pressure systems, off-the-shelf fittings might not offer the precision required. Custom designs enable engineers to tailor the material, structure, and connection methods to minimize leakage, enhance flow efficiency, and extend system longevity. The higher cost of customization is often justified by the reduction in downtime and improved safety in critical applications.

What Is the Proper Installation Process for Steel Hydraulic Fittings?

Correct installation of steel hydraulic fittings is paramount to system performance and durability. The process involves thorough preparation, precise alignment, and the correct use of tools to ensure a secure, leak-free connection. This section outlines a step-by-step procedure for installation, highlights the necessary tools and safety measures, and presents troubleshooting tips to address common installation challenges.

What Are the Step-by-Step Instructions for Installing Steel Hydraulic Fittings?

Begin by cleaning all components to remove debris and corrosion. Verify that each fitting meets the system’s specifications, including certification and dimensional tolerances. Align mating surfaces carefully and apply thread sealant or Teflon tape as needed. Tighten the fittings with the proper wrench and adhere to recommended torque settings to avoid damage. Finally, pressurize the system with hydraulic fluid and perform a leak test. If any leaks are detected, recheck the alignment and tighten further as necessary. This systematic approach ensures an efficient and durable installation.

What Tools and Safety Measures Are Required During Installation?

Essential tools for installation include adjustable wrenches, torque wrenches, pipe cutters, and cleaning brushes for preparing the connection surfaces. Safety measures such as wearing protective gloves and eyewear are necessary to prevent injury from hydraulic fluid or metal shards. Working in a well-ventilated area and following lockout/tagout procedures for pressurized systems further ensures safety. Using calibrated tools to apply the correct torque is critical to achieving secure and leak-free connections.

How to Troubleshoot Common Installation Issues?

Common installation issues include leaks, misalignment, and material incompatibility. Begin troubleshooting by checking that all fittings are tightened to the proper torque. Verify that components are aligned correctly; misalignment can cause improper seating and eventual failure. If pressure drops or unusual noises occur, inspect for internal damage or worn parts. In cases of fluid contamination, clean and replace affected components. Following manufacturer guidelines and standard procedures helps quickly resolve issues and minimizes system downtime.

How Do Steel Hydraulic Fitting Prices Compare Across Suppliers?

Supplier pricing for steel hydraulic fittings can vary significantly based on factors such as material quality, manufacturing standards, and additional services. Evaluating cost involves comparing base prices, certification, customization options, and logistics support. A comprehensive price comparison strategy, including assessing testimonials and performance test results, can help secure competitive pricing without compromising reliability.

What Factors Influence the Price of Steel Hydraulic Fittings?

Prices are influenced by the type of steel used (carbon versus stainless), the production methods (such as welding or crimping), and the complexity of the fitting design. Industry certifications and supplier reputation also play important roles. Bulk orders and customization needs may lead to discounts, while market fluctuations in raw material costs can affect overall pricing. For example, high-grade stainless steel fittings offer extended longevity, which may offset their higher initial cost.

How to Compare Prices From Different Hydraulic Fitting Suppliers?

Start by obtaining detailed quotations that include shipping, taxes, certification, and value-added service costs. Create a comparison table listing key metrics such as material type, unit price, lead time, and certification standards. Reviewing customer testimonials and requesting product samples for independent testing further assists in evaluating supplier performance objectively.

What Value-Added Services Affect Overall Cost?

Additional services such as technical support, certification checks, custom design consultations, and expedited delivery can affect the overall cost. Suppliers providing on-site training, after-sales support, and warranty guarantees may charge a premium, but the benefits can include reduced downtime and lower maintenance costs over the system’s lifetime. Evaluating these services alongside the base price gives a more complete picture of the overall investment.

Where to Find Reliable Steel Hydraulic Fitting Suppliers?

Finding a reliable supplier involves evaluating their reputation, certifications, product quality, and customer support. A dependable supplier meets international standards such as ANSI, ISO, and BSP, and provides comprehensive technical documentation and responsive after-sales service. Local suppliers may offer faster delivery and better communication, whereas international suppliers might provide access to a wider range of products and competitive pricing. Balancing these factors is key to securing high-quality fittings and long-term support.

What Qualities Define the Best Hydraulic Fitting Suppliers?

The best suppliers offer consistently high-quality products, hold comprehensive certifications, and provide excellent customer service. They maintain transparent quality control and invest in research and development to improve product performance. Strong after-sales support and positive customer testimonials are additional indicators of a reputable supplier.

How to Verify Supplier Certifications and Product Quality?

Review supplier documentation such as ISO certificates and test reports. Request samples for in-house testing or third-party evaluations, and check testimonials from other industrial users. Accredited trade associations and online performance reviews can further verify a supplier’s commitment to quality.

What Are the Benefits of Choosing Local vs. International Suppliers?

Local suppliers often deliver shorter lead times, easier communication, and on-site technical support. They may be more responsive during emergencies. International suppliers, however, can offer a broader product range and competitive pricing due to economies of scale, though they may have longer delivery times and potential language barriers. A balanced evaluation based on quality, cost, and support needs is essential.

How to Maintain and Extend the Life of Steel Hydraulic Fittings?

Proper maintenance extends the lifespan of hydraulic fittings and ensures ongoing system reliability. Regular cleaning, inspections, and timely repairs help prevent failures and reduce downtime. This section details routine maintenance practices, tips for detecting early signs of fitting failure, and guidelines for timely replacement.

What Routine Maintenance Practices Ensure Fitting Longevity?

Key practices include regular cleaning of components, visual inspections for corrosion, micro-cracks, or leaks, and timely lubrication of moving parts. Periodic pressure tests help verify system integrity, while maintaining hydraulic fluid quality and filtering out contaminants prevents premature wear. Keeping detailed maintenance records enables early detection of potential issues.

How to Detect and Prevent Common Fitting Failures?

Monitor for symptoms such as fluid leaks, pressure drops, and unusual vibrations. Use pressure gauges and ultrasonic detectors during routine inspections to identify early deterioration. Preventive measures include proper installation techniques, correct torque application, and timely replacement of worn seals and gaskets. A systematic maintenance plan can mitigate failure risks before they escalate into major issues.

When Should Steel Hydraulic Fittings Be Replaced?

Replace fittings when they no longer meet performance standards or show irreversible damage such as severe corrosion, cracks, or persistent leaks despite maintenance efforts. Regular evaluation during scheduled inspections helps determine when replacement is necessary. Operating with degraded fittings can compromise safety and increase downtime, so timely replacement is a sound investment.

Table: Comparison of Key Attributes for Steel Hydraulic Fittings

Before selecting fittings or suppliers, consider how material composition and design affect performance. The table below summarizes key attributes:

Fitting Type | Material Type | Pressure Rating (PSI) | Corrosion Resistance | Cost-effectiveness |

Carbon Steel | Carbon Steel | 3,000 – 5,000 | Moderate | High initial value |

Stainless Steel | Stainless Steel | 3,000 – 5,500 | Excellent | Higher upfront cost |

Alloy Steel | Alloyed with elements | 3,500 – 6,000 | Good | Moderate |

Custom Fittings | Varies (custom metal) | Depends on design | Tailored for environment | Increased cost with customization |

Standard Fittings | Carbon or Stainless | Standard ratings | Industry standard | Competitive pricing |

Following the table, engineers and procurement specialists can use this concise overview to evaluate which fitting best suits their hydraulic system requirements.

How to Maintain and Extend the Life of Steel Hydraulic Fittings? (Additional List)

- Regular Inspection – Check for corrosion, cracks, and leaks every 3 to 6 months.

- Proper Cleaning – Remove dirt, hydraulic fluid residue, and corrosion by-products with appropriate cleaning agents.

- Lubrication – Apply high-quality lubricants to moving parts and connection threads.

- Pressure Testing – Perform routine pressure tests to verify integrity.

- Documentation – Keep detailed logs of maintenance activities to track trends and schedule timely replacements.

Frequently Asked Questions

Q: What is the key advantage of using steel hydraulic fittings over other materials?

A: They offer superior strength, durability, and corrosion resistance, making them ideal for high-pressure, high-temperature applications and reducing long-term maintenance costs.

Q: How often should hydraulic fittings be inspected for maintenance?

A: Inspections should occur every 3 to 6 months to detect early signs of wear and prevent failures.

Q: Can I mix carbon steel and stainless steel fittings in the same system?

A: While technically possible, mixing materials can lead to galvanic corrosion. It is generally best to use fittings made from the same material.

Q: How do I confirm that my hydraulic fittings meet industry standards?

A: Verify that fittings carry certifications such as ANSI, ISO, or BSP and review the provided documentation and test reports from suppliers.

Q: What causes hydraulic fittings to fail prematurely?

A: Causes include improper installation, over-torquing, fluid contamination, and inconsistent maintenance. Following correct procedures minimizes these risks.

Q: Is professional installation necessary for hydraulic fittings?

A: Yes, professional installation ensures proper alignment, sealing, and correct torque, reducing the risk of leaks and system failures.

Q: What are common troubleshooting steps if a hydraulic fitting leaks?

A: Begin by checking the tightness of the connection and the proper application of sealants. If leaking persists, reposition the fitting, inspect for damage, and replace worn seals as needed. Consulting a professional may be required for persistent issues.