Hose fittings are connectors that join hoses to pumps, valves, pipes, or machinery. They ensure secure fluid transfer across applications such as gardening, manufacturing, automotive, and heavy equipment. Local suppliers typically stock a diverse inventory covering general‐purpose to specialized fittings.

Which Garden Hose Fittings Can I Buy Locally?

Garden hose fittings include couplers, adapters, and valves designed for water pressure up to 100 psi. Local stores often carry:

- Brass male and female connectors for corrosion resistance

- Plastic quick-connect adapters for ease of use

- Swivel couplings for twisting without kinking

These components improve watering efficiency and prevent leaks. Understanding garden fitting sizes leads naturally into industrial alternatives.

What Industrial Hose Fittings Are Offered Nearby?

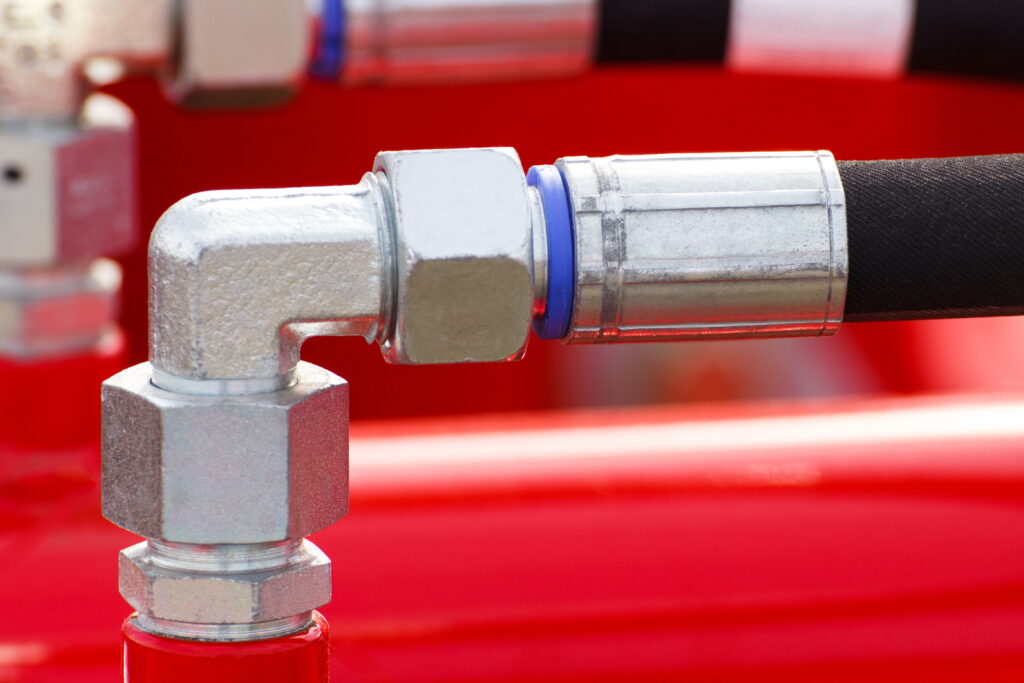

Industrial fittings handle higher pressures (up to 600 psi) and aggressive fluids.

- Stainless steel compression fittings for corrosive liquids

- Carbon‐steel crimp fittings for hydraulic fluid

- Cam-and-groove couplings for quick equipment changeovers

Local inventory ensures immediate availability, reducing production delays. Next, explore fittings for hydraulics and air systems.

Where to Find Hydraulic and Air Hose Fittings Locally?

Hydraulic and pneumatic applications demand precision-engineered fittings rated for pressures from 1,000 psi to 5,000 psi.

- Flared‐tube fittings compatible with fuel line systems

- O-ring face seal (ORFS) fittings preventing hydraulic fluid leaks

- Push-to-connect fittings for air tools and vacuum lines

These connectors maintain system integrity under high pressure, setting the stage for specialty fitting options.

What Specialty Hose Fittings Are Available Near Me?

Specialty fittings address niche needs in welding, oil transfer, and chemical handling. Typical local stock features:

- Gasketed fittings for fuel pumps and tanks

- Vacuum‐rated stainless steel adapters

- High-heat brass fittings for pressure washing or steam applications

Identifying specialty components clarifies selection criteria covered in the next section.

How Do I Choose the Right Hose Fitting Near Me?

Selecting the ideal fitting balances material compatibility, size accuracy, and application demands. The wrong choice risks leaks, damage, or downtime.

What Hose Fitting Materials Should I Consider?

Material selection influences durability and chemical resistance:

Material Attribute Benefits Brass Corrosion resistance Ideal for water, air, mild acids Stainless steel Strength & hygiene Suited to food, chemicals, high heat Carbon steel High pressure rating Best for heavy equipment hydraulics Plastic (Nylon, PVC) Lightweight Economical for gardening

Hose Fitting Materials and Applications

Selecting the right material for hose fittings is crucial for ensuring durability and performance, with options like brass for corrosion resistance and stainless steel for strength and hygiene. Carbon steel is often favored for high-pressure applications, while plastics like nylon and PVC offer lightweight and economical solutions. Matching the fitting material to the fluid and pressure requirements maximizes the service life and efficiency of the system.

Smith, J., “Material Selection Guide for Hose Fittings” (2023)

Matching material to fluid and pressure maximizes service life and performance, guiding size and type determination.

How to Determine the Correct Hose Fitting Size and Type?

Accurate sizing prevents leaks and pressure loss:

- Measure hose I.D. and O.D. with calipers for precision.

- Check pump or valve thread standard (NPT, BSP, metric).

- Select fitting style—barbed, crimp, compression—based on hose reinforcement.

- Confirm pressure rating meets system requirements.

Correct sizing ensures safety and efficiency, leading to application-specific recommendations.

Which Hose Fittings Are Best for Specific Applications?

Different tasks require tailored fittings:

- Automotive Fuel Lines: Use stainless steel ORFS fittings with gasket seals.

- Pressure Washing: Choose brass quick-disconnect couplers rated above 2,500 psi.

- Pneumatics: Opt for push-to-connect nylon fittings compatible with air compressors.

Matching fitting style to use case enhances longevity and reduces maintenance.

Where Can I Buy Hose Fittings Near Me? Local Stores and Suppliers

Supporting local businesses yields faster service, expert guidance, and immediate inventory access. Here’s how to find reliable outlets.

What Are the Benefits of Buying Hose Fittings Locally?

Buying nearby delivers:

- Instant inventory access without shipping delays

- In‐person expert advice on selecting and installing fittings

- Hands-on inspection of brass, steel, or plastic connectors

- Potential for on-site crimping or cutting services

These advantages streamline procurement and reduce project downtime.

Benefits of Buying Hose Fittings Locally

Purchasing hose fittings from local suppliers offers several advantages, including immediate access to inventory, expert advice, and the potential for on-site services like crimping and cutting. This approach reduces shipping delays and provides opportunities for hands-on inspection of the products, which streamlines procurement and minimizes project downtime. Local suppliers often provide installation services and warranties, ensuring leak-free connections and extended hose life.

Johnson, A., “The Advantages of Local Supply Chains in Industrial Settings” (2022)

How to Find Reliable Local Hose Fitting Stores?

Locate reputable suppliers by:

- Checking online reviews on Google and local directories

- Visiting shops with large inventory and organized tool displays

- Asking for certification or brand partnerships (Hydraulic Institute, SAE)

- Verifying availability of installation services and warranties

Reliable stores often carry top brands and maintain wide stock levels.

Do Local Suppliers Offer Installation Services for Hose Fittings?

Many local suppliers provide complementary or paid installation:

- Hydraulic hose crimping and testing

- Thread assembly and gasket fitting

- On-site fabrication for custom lengths

- Pressure-testing services for quality assurance

Professional installation ensures leak-free connections and extended hose life.

What Are the Prices of Hose Fittings Near Me?

Local pricing varies by material, brand, and quantity. Understanding cost drivers helps you budget effectively.

How Do Local Hose Fitting Prices Compare to Online Options?

Local prices might be 5–15% higher than some e-commerce rates due to overhead, but savings include:

- No shipping fees or wait times

- Expert consultation and installation packages

- Immediate replacement options

Total value often outweighs minor price differentials.

Are There Discounts or Promotions at Local Hose Fitting Stores?

Seasonal or bulk discounts can reduce costs:

- Volume pricing on cartons of stainless steel adapters

- Promotional bundles combining hoses, clamps, and fittings

- Loyalty programs offering future purchase credits

Inquire about current deals to maximize savings on brass, steel, or compression fittings.

What Factors Affect Hose Fitting Prices Locally?

Key price influencers include:

- Material grade (304 vs. 316 stainless steel)

- Pressure rating (standard vs. high‐pressure versions)

- Brand reputation (industrial leaders vs. generic lines)

- In-stock vs. special-order items

Understanding these variables helps balance cost and performance.

How Can I Install and Maintain Hose Fittings Purchased Near Me?

Proper installation and ongoing maintenance ensure reliable operation and reduce equipment downtime.

What Are the Steps to Properly Connect Hose Fittings?

Follow these general steps:

- Cut hose squarely with a specialized hose cutter.

- Slide clamp or nut onto hose end.

- Insert fitting shank fully into hose.

- Tighten clamp or torque nut to manufacturer’s spec.

- Pressure-test assembly at recommended psi.

Adhering to these steps prevents leaks and extends hose life.

How Do I Repair or Replace Hose Fittings Locally?

Repair or replacement involves:

- Identifying damaged sections and selecting matching fittings

- Visiting local supplier for crimping or thread assembly

- Pressure-testing before returning to service

- Recycling old sections at participating retailers

Local shops often expedite emergency repairs for critical systems.

What Maintenance Tips Keep Hose Fittings Durable?

Routine care extends fitting service life:

- Inspect connections monthly for wear or leaks

- Clean fittings to remove debris and prevent corrosion

- Re-torque clamps after initial operation

- Store hoses hung off the floor to avoid kinks

Consistent maintenance reduces replacement costs and safeguards productivity.

What Do Customers Say About Local Hose Fitting Suppliers Near Me?

Customer experiences reveal supplier reliability, service quality, and product performance.

Where Can I Find Reviews of Local Hose Fitting Stores?

Check reviews on:

- Google Business Profiles for detailed customer feedback

- Industry forums (manufacturing, automotive)

- Social media pages showing before-and-after installations

- Local chamber of commerce directories

Evaluating reviews uncovers trustworthiness and service standards.

How Do Customer Experiences Influence Choosing Local Hose Fittings?

Positive signals include:

- High ratings for customer service and expert advice

- Testimonials on reduced downtime and leak-free performance

- Word-of-mouth referrals for urgent emergency repairs

Real-world feedback guides confident purchasing decisions.

Which Hose Fitting Brands Are Available Near Me?

Brand selection affects compatibility, reliability, and warranty coverage.

What Are the Top Hose Fitting Brands Carried by Local Suppliers?

- Parker Hannifin – known for hydraulic and industrial fittings

- Dixon Valve – specializing in cam-and-groove couplings

- Swagelok – premium stainless steel compression fittings

- Banjo – durable brass and steel agricultural fittings

Top Hose Fitting Brands and Quality

Leading hose fitting brands, such as Parker Hannifin, Dixon Valve, Swagelok, and Banjo, are known for their consistent quality and reliability across various applications. These brands offer material traceability, precise tolerances, and comprehensive warranty coverage, which are critical for ensuring leak-proof seals and overall system performance. Choosing a reputable brand ensures performance and peace of mind.

Brown, C., “Brand Reputation and Performance in Fluid Power Systems” (2024)

How Do Brand Differences Affect Hose Fitting Quality and Price?

Brand impacts:

- Material traceability and certification

- Tolerance precision for leak-proof seals

- Warranty lengths and technical support

- Price tiers from economy to premium

Selecting a reputable brand ensures performance and peace of mind.

Reliable local suppliers make it easy to compare these brands side by side, reinforcing sound purchasing choices.

Our exploration begins by detailing the types of plumbing fittings a top company offers, then explains selection criteria, installation methods, and supplier evaluation. Whether you need standard pipe products or specialized corrosion-resistant components, this guide addresses common questions for plumbing contractors and DIYers alike.

What Types of Plumbing Fittings Does a Leading Fittings Company Offer?

A leading plumbing fittings company offers a comprehensive range of products designed for various applications:

- Pipe Fittings: Made from PVC, CPVC, or metal, these fittings ensure leak-free connections and system integrity.

- Valve Fittings: Includes ball, gate, globe, and check valves that control flow and pressure in the system.

- Specialty Fittings: Custom-fabricated adapters, unions, flanges, expansion joints, and threaded or brazed connections designed for specialized projects such as irrigation or high-pressure assemblies.

Such suppliers also provide adapters, unions, and connectors to ensure compatibility among different fittings. This versatility helps counter issues like corrosion, pressure loss, and inefficiencies, while strong customer service and technical support distinguish top suppliers in a competitive market.

Which Pipe Fittings Are Essential for Plumbing Systems?

Essential pipe fittings serve as the foundation for every plumbing system:

- Components: Elbows, tees, reducers, couplings, and caps. For example, elbows facilitate directional changes and tees allow branching to supply or remove water from multiple points. • Materials: PVC and CPVC are lightweight and chemically resistant, ideal for domestic systems. Brass and stainless steel fittings provide extra durability and corrosion resistance for high-pressure or harsher environments. • Quality Assurance: Top suppliers rigorously test fittings according to industry standards such as ASTM or ISO. Variations in finishes also cater to specific aesthetic or functional needs, such as in hospitals or laboratories.

By selecting fittings with robust quality control and design, professionals can ensure long-lasting, reliable installations that manage pressure discrepancies and minimize leaks.

What Valve Fittings Are Available and When Should You Use Them?

Valve fittings are vital for regulating flow, pressure, and temperature in both plumbing and industrial systems:

- Common Types:

– Ball Valves: Feature a spherical closure for a tight shutoff; ideal for systems requiring frequent operation.

– Gate Valves: Use a sliding gate for isolating pipeline sections with minimal pressure drop.

– Globe Valves: Provide precision flow control, balancing temperature and pressure.

– Check Valves: Prevent backflow, protecting pipes and eliminating water hammer.

- Material Choices: Options include brass, stainless steel, or PVC. Brass valves are popular in low-to-medium pressure systems for their corrosion resistance and cost-effectiveness, while stainless steel valves are preferred in high-pressure or chemically aggressive settings due to their durability.

Choosing the right valve fitting depends on the system’s operating pressure, required shutoff speed, and material compatibility.

What Specialty Fittings Should You Consider for Custom Plumbing Needs?

Custom plumbing projects benefit from specialty fittings that go beyond standard solutions:

- Types:

– Adapters and Unions: For connecting dissimilar materials or accommodating unique pipe sizes.

– Flanges and Expansion Joints: Handle high-pressure conditions or allow for thermal expansion in long pipe runs.

– Unique Couplings: Engineered for specific load and spatial requirements, ensuring secure, reusable seals.

- Customization: Working directly with suppliers facilitates product tailoring. Detailed engineering drawings, material certifications, and performance data ensure that custom solutions meet strict building codes and project demands.

These fittings address unique challenges and reduce future maintenance costs, particularly in specialized applications like chemical processing or industrial cooling.

How to Select the Best Fittings for Plumbing: Materials and Durability Explained

Selecting the right fittings involves evaluating several key factors:

- Operating Environment: Consider water quality, pressure, temperature, and chemical exposure.

- Material Options:

– Copper: Excellent durability and thermal conductivity for residential hot water systems.

– PVC/CPVC: Lightweight, affordable options with chemical resistance; CPVC is better suited for higher temperatures and pressures.

– Brass and Stainless Steel: Preferred for applications requiring high corrosion resistance and mechanical strength.

- Durability Testing: Consult technical data sheets, including burst pressure and cyclic fatigue tests, to ensure the fitting’s longevity.

Balancing performance, cost, and durability based on project demands and adhering to industry standards leads to better system reliability and reduced maintenance.

What Are the Advantages of Copper, PVC, and CPVC Fittings?

- Copper Fittings:

– Offer superior longevity and natural antimicrobial properties that inhibit bacterial growth.

– Tolerate high temperatures and pressures, making them essential in hot water distribution despite higher cost.

- PVC Fittings:

– Lightweight, cost-effective, and simple to install using adhesives.

– Best for low-pressure, chemically inert applications.

- CPVC Fittings:

– Combine PVC’s affordability with added heat resistance. – Suitable for both cold and hot water systems in more demanding industrial or commercial settings.

Each material’s benefits must be weighed against project needs, maintenance ease, and budget considerations.

Why Choose Brass or Stainless Steel Fittings for Long-Lasting Performance?

- Brass Fittings:

– Known for excellent corrosion resistance and reliable sealing. – Provide durability in residential and moderate commercial settings at a reasonable cost.

- Stainless Steel Fittings:

– Offer exceptional strength and high corrosion resistance, crucial for high-pressure or aggressive environments. – Non-reactive properties ensure water quality is maintained, especially in sensitive applications like medical or food processing systems.

Both materials undergo strict quality control and are backed by certifications, ensuring dependable performance and reduced maintenance over time.

How Do Eco-Friendly Fittings Options Compare to Traditional Materials?

Eco-friendly fittings are gaining attention as sustainable alternatives that do not compromise on performance:

- Sustainable Features:

– Made using recycled metals, bio-based polymers, and low-emission production methods.

– Support green building certifications such as LEED or Green Seal.

- Performance:

– Often match or exceed traditional fittings in corrosion resistance and durability.

– Can lower lifecycle costs by reducing energy consumption and maintenance needs.

Choosing eco-friendly options aligns with sustainability goals while maintaining high functional standards in plumbing systems.

What Are the Steps for Proper Fittings Installation?

Proper installation is crucial for preventing leaks and ensuring long-term system performance:

- Preparation:

– Thoroughly inspect and clean all pipes.

– Measure, cut, and deburr pipes accurately to create smooth surfaces.

- Assembly:

– Use the proper adhesives for PVC/CPVC or soldering for copper, and ensure threaded connections are tightened to the recommended torque levels. – Follow manufacturer guidelines and local codes during assembly.

- Testing:

– Inspect joints and use pressure testing to confirm leak-free connections. – Address misalignments or insufficient bonding immediately to prevent system failure.

A systematic approach and correct tool usage are essential for reliable, long-lasting installations.

How to Prepare Plumbing Systems for Fittings Installation?

Effective preparation is the foundation of proper installation:

- Clean pipes thoroughly with appropriate solvents or abrasives.

- Measure and cut pipes precisely, deburring edges to prevent damage.

- Mark installation points to ensure proper alignment.

Adequate workspace conditions such as proper lighting and ventilation also contribute to a smoother installation process and enhance overall system durability.

What Tools and Techniques Ensure Secure Pipe and Valve Fittings?

Secure connections require the use of specialized tools and techniques:

- Tools: Pipe cutters, deburring tools, wrenches, soldering irons, adhesives, and clamps. • Techniques:

– Apply consistent torque on threaded fittings. – Use controlled heating for soldering. – Follow manufacturer guidelines for adhesive application on PVC/CPVC.

Regular pressure testing and adherence to standardized procedures confirm the integrity of the assembly, reducing future leaks and maintenance needs.

How to Troubleshoot Common Fittings Installation Issues?

Even with careful installation, some issues may arise:

- Look for leaks, misaligned joints, or weak adhesive bonds. • Use pressure gauges to detect drops in pressure indicating potential leaks. • Re-tighten or re-solder problematic joints and reapply adhesives as needed.

Consult troubleshooting guidelines provided by manufacturers and local codes to ensure corrective measures maintain overall system performance.

Why Choose a Trusted Plumbing Fittings Supplier for Your Projects?

Working with a trusted supplier provides significant advantages:

- Product Quality: Suppliers with rigorous quality control and a broad inventory deliver reliable products. • Expert Support: Technical representatives provide guidance on material selection and installation methods.

- Logistics: Fast, reliable delivery and comprehensive order tracking minimize project delays. • Convenience: A wide product selection from one source simplifies procurement and logistics, especially for large projects.

Reliability and expert advice from a reputable supplier enhance both initial installation quality and long-term system performance.

How Does Expert Advice Improve Your Fittings Selection?

Expert advice is invaluable in navigating complex plumbing projects:

- Professionals benefit from recommendations on optimal materials and techniques. • Technical experts assess project specifications to suggest fittings that reduce corrosion and manage thermal expansion. • Such advice ensures compliance with local codes and enhances overall system performance while reducing installation errors.

The result is a more reliable, cost-effective, and durable plumbing system.

What Delivery Options Ensure Fast and Reliable Supply?

Trusted suppliers offer various delivery options to meet project timelines:

- Options include same-day, next-day, or expedited shipping. • Shipment tracking systems provide real-time updates for transparency. • Regional distribution centers and carrier partnerships ensure timely, accurate order fulfillment, even during peak construction periods or emergency repairs.

Reliable delivery minimizes downtime and helps keep projects on schedule.

How Does a Wide Product Selection Benefit Plumbing Professionals and DIYers?

A broad product range offers benefits for both professionals and DIY enthusiasts:

- For professionals, a single source for all fittings—standard, custom, and eco-friendly—simplifies procurement, reduces lead times, and improves response to challenges. • DIYers can easily find components that match specific project needs, compare sizes and materials, and access detailed technical specifications. • Comprehensive catalogs and expert support lead to safer, more efficient, and longer-lasting installations.

What Are the Latest Trends in Eco-Friendly Plumbing Fittings?

Sustainability is reshaping the plumbing industry, and eco-friendly fittings are at the forefront:

- Innovations: Manufacturers are developing fittings using recycled metals, bio-based polymers, and green production processes. • Performance: These fittings are engineered to match or exceed the durability and corrosion resistance of traditional materials while reducing the carbon footprint. • Certifications: Eco-friendly products support green building standards like LEED, making them attractive for sustainable projects. • Cost Savings: Reduced energy consumption and lower maintenance needs further enhance their appeal.

These trends help balance high performance with environmental responsibility.

Which Sustainable Materials Are Gaining Popularity in Plumbing Fittings?

Key sustainable materials include:

- Recycled Metals: Brass and stainless steel fittings produced from recycled materials deliver high performance with lower environmental impact. • Bioplastics: Innovative bio-based polymers offer durability similar to PVC/CPVC without relying on fossil fuels. • Testing and Certification: These materials are rigorously tested for pressure ratings and corrosion resistance, and are endorsed by green building councils.

Their integration supports environmental conservation and long-term cost savings.

How Do Eco-Friendly Fittings Contribute to Green Building Standards?

Eco-friendly fittings help buildings meet green standards by:

- Reducing embodied energy and waste during production. • Supporting certifications like LEED through improved energy efficiency and reduced water waste. • Streamlining maintenance and extending the system’s lifecycle, which lowers the overall carbon footprint.

Using sustainable fittings assists contractors in achieving both functionality and environmental responsibility.

Where Can You Find Certified Eco-Friendly Plumbing Fittings?

Certified eco-friendly fittings can be sourced from:

- Reputable suppliers specializing in sustainable products. • Suppliers that display certifications such as LEED, Green Seal, or ISO 14001. • Trade shows, green building conferences, and dedicated online catalogs where detailed product information and customer testimonials are available.

This ensures that every installation aligns with the highest environmental standards.

How Can Custom Pipe Fittings Solve Unique Plumbing Challenges?

Custom pipe fittings offer tailored solutions for complex plumbing challenges:

- They address unique requirements like unusual loads, non-standard pipe sizes, or specific pressure ratings. • Engineering consultations help design fittings that perfectly match the project needs using CNC machining, laser cutting, or precision casting. • Custom options often include proprietary sealing or coating for enhanced corrosion and pressure resistance, reducing future maintenance costs.

These solutions ensure optimal performance in specialized industrial or commercial applications.

What Are the Benefits of Custom-Made Fittings for Industrial Applications?

In industrial settings, custom-made fittings provide:

- Improved system performance and safety by conforming exactly to specifications. • Reduced downtime thanks to fewer on-site adjustments and modifications. • Seamless integration with existing systems, leading to lower leakage and maintenance costs.

Their precise engineering protects against catastrophic failures and enhances overall operational efficiency.

How to Request and Design Custom Pipe Fittings?

The process for custom fittings typically involves:

- Initial consultation with the supplier’s technical team to discuss project dimensions, pressure ratings, and material choices. • Creating detailed design specifications and blueprints based on project challenges. • Using advanced manufacturing methods such as CNC machining or laser cutting to produce and test a prototype before final production. • Continued communication ensures the final product meets the strict project requirements.

This collaborative approach results in custom fittings that optimize both reliability and efficiency.

What Are Common Materials and Specifications for Custom Fittings?

Common choices for custom fittings include:

- Materials: High-grade brass, stainless steel, reinforced PVC, or CPVC depending on temperature, pressure, and chemical exposure requirements. • Specifications: Precise diameter, wall thickness, pressure ratings, and connection types (e.g., threaded, flanged) are detailed in technical documentation. • Quality Assurance: Manufacturers provide certifications and stress test results to ensure compliance with international standards like ASTM or ISO.

Adhering to these specifications ensures a perfect fit and long-term system integrity.

What Do Customers Say About the Best Plumbing Fittings Companies?

Customer feedback underscores the importance of quality and service in the plumbing fittings market:

- Reviews highlight the durability, performance, and ease of installation of high-quality fittings. • Customers appreciate timely delivery, comprehensive technical support, and a wide product range from reliable suppliers. • Positive testimonials and consistent case studies reinforce the value of expert advice and responsive customer service. • Feedback from both professionals and DIYers guides future customers in making informed purchasing decisions.

Reliability and customer satisfaction are key indicators when evaluating a supplier’s performance.

How Do Plumbing Professionals Rate Their Supplier Experience?

Plumbing professionals emphasize:

- High satisfaction with product reliability and comprehensive technical support. • The importance of rapid turnaround on custom orders and reliable post-sales assistance. • Detailed technical documentation and on-demand consultation that enhance confidence in project outcomes. • Consistent positive experiences lead to long-term partnerships and improved system performance.

What Are the Most Popular Fittings Among DIY Enthusiasts?

DIY enthusiasts favor fittings that are:

- Easy to install with minimal specialized tools, such as PVC and CPVC fittings. • Cost-effective yet durable, with brass fittings often chosen for small-scale projects. • Supported by plentiful online reviews and instructional videos that simplify installation. • Available from suppliers providing clear product details and strong customer service.

These factors collectively contribute to safer and more efficient home plumbing projects.

How Do Customer Reviews Reflect Product Quality and Service?

Customer reviews provide valuable insights by noting:

- Consistency in longevity, corrosion resistance, and installation ease. • Responsive customer service—from prompt order processing to knowledgeable technical support. • Detailed feedback on installation times and post-installation performance, helping suppliers refine their offerings. • Transparency through independent testing and certification, boosting confidence among new customers.

Table: Comparison of Plumbing Fitting Materials

Material | Advantages | Common Uses | Performance Rating |

Copper | Durable, antimicrobial, heat resistant | Residential hot water systems | High |

PVC | Lightweight, cost-effective, chemical resistant | Low-pressure water supply | Medium |

CPVC | Heat resistant, versatile | Commercial water systems | Medium-High |

Brass | Corrosion resistant, strong | Valves and joints | High |

Stainless Steel | Extremely durable, high corrosion resistance | High-pressure/industrial systems | Very High |

This table summarizes each material’s benefits, common applications, and overall performance, making it easier for professionals to choose the best option for their project needs.

Frequently Asked Questions

Q: What are the key factors to consider when selecting plumbing fittings?

A: Consider the operating environment (temperature, pressure, and water quality), material durability (corrosion resistance and tensile strength), compatibility with other system components, and installation requirements. Additionally, cost, availability, and supplier support are crucial for long-term reliability.

Q: How do eco-friendly plumbing fittings compare to traditional options?

A: Eco-friendly fittings use sustainable materials and production methods to lower environmental impact, while still matching traditional fittings in durability and performance. They often support green building certifications and can reduce lifecycle costs through lower energy and maintenance needs.

Q: Can custom pipe fittings be made to meet specific project needs?

A: Yes. Custom fittings are designed and manufactured based on precise specifications. They address unique challenges such as non-standard pipe sizes, thermal expansion, or high-pressure conditions. This tailored approach minimizes installation time and future maintenance issues.

Q: What delivery options should I expect from a reputable fittings supplier?

A: Reputable suppliers offer fast, reliable delivery including same-day, next-day, or expedited shipping. They provide comprehensive order tracking and have robust logistics networks to ensure timely and accurate fulfillment.

Q: Why are brass and stainless steel preferred for high-performance plumbing systems?

A: Both materials offer exceptional durability and corrosion resistance. Brass is ideal for moderate environments due to its ease of installation and cost-effectiveness, while stainless steel is favored in high-pressure or chemically aggressive settings for its superior strength and non-reactive properties.

Q: What benefits do expert technical advisors provide when choosing fittings?

A: Expert advisors help analyze project needs, recommend optimal materials and installation methods, and ensure adherence to local codes and industry standards. Their guidance minimizes installation errors and enhances overall system performance.

Q: How important is system preparation before installing plumbing fittings?

A: System preparation is critical. Proper cleaning, precise cutting, and accurate alignment of pipes ensure that fittings bond correctly and function as intended, minimizing the risk of leaks and installation failures.