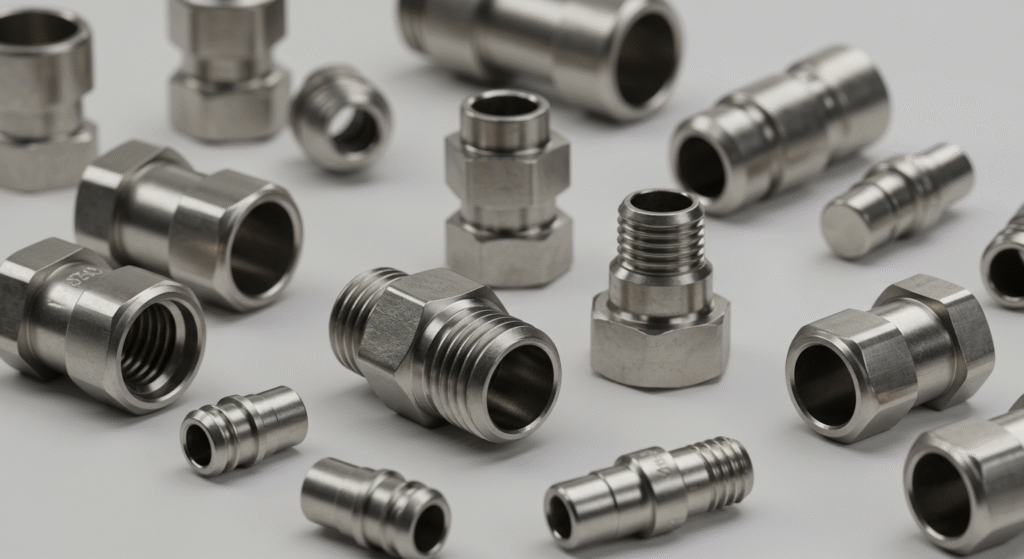

Up to 80% of fluid-system leaks originate at poorly selected connection points, resulting in costly downtime and safety hazards. Stainless steel compression fittings eliminate these vulnerabilities by combining robust material properties with precise sealing mechanics. Industrial buyers and field technicians in oil & gas, energy, and chemical processing sectors rely on stainless steel compression fittings for high-pressure, corrosion-prone applications. This article defines how these fittings work, compares material grades for extreme conditions, surveys key use cases, specifies performance characteristics, and details installation, maintenance, and selection strategies to ensure leak-proof, long-lasting connections. Explore our stainless steel compression fittings product line for tailored solutions.

What Are Stainless Steel Compression Fittings and How Do They Work?

A stainless steel compression fitting is a mechanical connector that uses a ferrule-and-nut assembly to seal tubing without welding or flaring. By compressing the ferrule onto the tube surface inside the fitting body, it forms a metal-to-metal seal that resists vibration and temperature cycles. For example, in an offshore hydraulic manifold, this mechanism maintains integrity under 3,000 psi and saltwater spray. Understanding this sealing principle allows engineers to deploy leak-proof connections in demanding industrial lines and instrumentation systems.

What Is a Compression Fitting and Its Key Components?

A compression fitting consists of three primary parts—nut, ferrule, and body—that work together to secure tubing and prevent leaks.

- Nut: Threads onto the fitting body to drive ferrule compression.

- Ferrule: A split, ring-shaped sleeve that deforms around the tube when tightened.

- Body: Houses the ferrule and provides the pathway for fluid flow.

- Tubing: The stainless steel tube inserted into the fitting for fluid transfer.

Each component must meet strict dimensional tolerances to guarantee uniform deformation and repeatable leak-proof performance. Proper alignment of the ferrule on the tubing shoulder initiates the sealing action that withstands pressure spikes and mechanical stress.

How Do Stainless Steel Compression Fittings Ensure Leak-Proof Connections?

Stainless steel compression fittings achieve leak-proof integrity through controlled ferrule deformation and metal-to-metal contact. As the nut is torqued, the ferrule contracts radially and grips the tubing surface, creating a seal that blocks fluid escape and resists vibration loosening. This mechanism eliminates reliance on thread sealants or gaskets, minimizing maintenance and ensuring consistent performance under high pressure and temperature fluctuations.

What Makes Stainless Steel Suitable for Compression Fittings?

Stainless steel’s unique alloy composition—primarily chromium, nickel, and optional molybdenum—provides exceptional corrosion resistance, tensile strength, and temperature tolerance. These properties protect fittings from pitting, crevice attack, and stress corrosion cracking in chloride-rich or acidic environments. High yield strength prevents deformation under pressure, while a broad service range (–65 °C to 400 °C) enables applications from cryogenic systems to high-heat refinery lines. Such material advantages underpin the durability and reliability demanded by critical industrial processes.

Corrosion Resistance of Stainless Steel

Stainless steel’s resistance to corrosion is primarily due to the formation of a passive film, a chromium-rich oxide layer that protects the metal from reactive elements. This passive film is crucial for preventing pitting, crevice attack, and stress corrosion cracking in various environments.

American Iron and Steel Institute, Stainless Steel: The Basics (2022)

This research supports the article’s explanation of how stainless steel resists corrosion through passive film formation.

Which Stainless Steel Grades Are Best for High-Demand Industrial Applications?

Selecting the right stainless steel grade aligns material properties with environmental challenges and performance requirements. Grades differ in alloy content, mechanical strength, and corrosion-fighting mechanisms to suit specific service conditions.

Grade | Key Alloying Elements | Primary Benefit |

316 Stainless Steel | 16–18% Cr, 10–14% Ni, 2–3% Mo | Superior pitting and crevice corrosion resistance in chloride environments |

Duplex Stainless Steel | 20–23% Cr, 4–6% Ni, 3–5% Mo | Balanced ferritic-austenitic structure for high strength and corrosion resistance |

Super Duplex Stainless | 24–26% Cr, 6–8% Ni, 3–5% Mo | Enhanced chloride stress corrosion cracking resistance and up to 20% greater strength |

Stainless Steel Grades and Applications

Different grades of stainless steel, such as 316, Duplex, and Super Duplex, offer varying levels of corrosion resistance and mechanical strength due to their unique alloy compositions. These grades are selected based on the specific environmental challenges and performance requirements of the application.

ASM International, Metals Handbook, Volume 13: Corrosion (2019)

This source provides further detail on the different grades of stainless steel and their suitability for various industrial applications, as discussed in the article.

These grades use passive-film mechanisms and alloy reinforcements to combat localized attack. Understanding grade-specific advantages guides engineers in matching fittings to offshore, chemical, or high-pressure service needs.

What Are the Benefits of 316 Stainless Steel in Harsh Environments?

316 stainless steel incorporates molybdenum to bolster resistance against pitting and crevice corrosion. This enhancement makes 316 ideal for saltwater systems on offshore platforms and brine-handling lines in desalination plants. Its stable passive layer also resists sulfuric and phosphoric acids in processing facilities, providing durable, low-maintenance connections.

How Do Duplex and Super Duplex Stainless Steel Enhance Performance?

Duplex and Super Duplex grades combine ferritic and austenitic microstructures to deliver double the yield strength of 316 while maintaining excellent corrosion resistance. This high strength-to-weight ratio enables thinner-walled fittings in limited-space assemblies and withstands pressure surges exceeding 10,000 psi. Their resistance to chloride stress corrosion cracking extends service life in subsea and petrochemical environments.

What Corrosion Resistance Mechanisms Protect Stainless Steel Fittings?

Stainless steel employs three primary corrosion-fighting strategies:

- Passive Film Formation – A chromium-rich oxide layer shields the metal from reactive species.

- Pitting Resistance – Molybdenum content in 316 and duplex grades stops pit initiation in chloride media.

- Stress Corrosion Cracking Inhibition – Balanced microstructures and controlled residual stresses prevent cracking under tensile loads in corrosive settings.

These mechanisms work in concert to maintain fitting integrity where non-stainless materials would fail rapidly.

In Which High-Demand Environments Are Stainless Steel Compression Fittings Most Effective?

Stainless steel compression fittings excel wherever systems face high pressure, aggressive chemicals, saltwater exposure, or thermal cycling. Their proven reliability makes them the connection method of choice across multiple critical sectors.

- Oil and Gas Exploration – High-pressure well-head manifolds and downhole sampling lines.

- Chemical Processing Plants – Pipelines carrying corrosive acids, solvents, and steam.

- Marine and Offshore Platforms – Saltwater-immersed hydraulic and instrumentation tubing.

- Power Generation Systems – High-temperature steam loops, turbine lubrication circuits, and vibration-intense conduits.

This versatility underpins the widespread adoption of stainless steel compression fittings in environments where safety and uptime are paramount.

Why Are Stainless Steel Fittings Preferred in the Oil and Gas Sector?

Oil and gas operations demand leak-proof, high-pressure connections that resist sour gas corrosion and vibrating pump skid installations. Stainless steel fittings meet API and NACE standards, deliver consistent torque-to-seal performance, and minimize downtime during maintenance cycles on offshore platforms and FPSO modules.

How Do These Fittings Perform in Chemical Processing Plants?

In chemical plants, compatibility with aggressive fluids and alkalis is critical. Stainless steel compression fittings resist attack from acids and chlorides, maintain seal integrity through thermal swings, and eliminate the risk of contaminant ingress, ensuring process purity and safety.

What Advantages Do Stainless Steel Fittings Offer in Marine and Offshore Environments?

Saltwater immersion accelerates corrosion on many alloys, but stainless steel’s passive film repels chloride ions and prevents localized pitting. Combined with vibration resistance, this durability ensures reliable hydraulic and instrumentation connections on ships, rigs, and subsea assemblies with minimal inspection frequency.

How Are Stainless Steel Compression Fittings Used in Power Generation and Energy Systems?

Power plants expose fittings to high-temperature steam, cycle-induced vibration, and abrasive particulates. Stainless steel compression fittings maintain pressure and temperature ratings up to 400 °C, preserve seal integrity under continuous oscillations, and support safe steam-to-water transitions in condensate return lines and turbine control circuits.

What Are the Key Performance Characteristics of Stainless Steel Compression Fittings?

Performance specifications define application suitability and safety margins for industrial systems. Key metrics include pressure rating, temperature range, leak integrity, vibration tolerance, and adherence to recognized standards.

Characteristic | Entity | Value/Specification |

Maximum Pressure Rating | PressureTolerance | Up to 10,000 psi (Duplex grades) |

Temperature Range | ThermalCompatibility | –65 °C to 400 °C |

Leak Integrity | SealPerformance | Bubble-tight per ANSI/FCI 70-2 Class V |

Vibration Resistance | MechanicalDurability | No loosening at ±2 g acceleration |

Governing Standards | RegulatoryCompliance | DIN 2353, ASTM A182, ISO 8434-1 |

What Pressure and Temperature Ratings Do These Fittings Support?

Standard 316 fittings reliably handle up to 6,000 psi and temperatures from –65 °C to 204 °C; Duplex variants extend pressure capacity beyond 10,000 psi and tolerate continuous operation up to 400 °C. Such ratings cover the majority of hydraulic, pneumatic, and steam applications.

How Do Stainless Steel Fittings Maintain Leak Integrity and Vibration Resistance?

Metal-to-metal sealing eliminates elastomer degradation risk, while ferrule design resists back-off under cyclic loading. Precision machining and controlled torque values deliver consistent compression, ensuring leak-free performance in vibrating installations such as reciprocating compressors and pump skids.

Which Industry Standards Govern Stainless Steel Compression Fittings?

Leading specifications include DIN 2353 for metric ferrule fittings, ASTM A182 for forged fitting bodies, and ISO 8434-1 for tube connectors, establishing material composition, dimensional tolerances, testing methods, and traceability requirements to guarantee safety and interchangeability.

How Should Stainless Steel Compression Fittings Be Installed and Maintained for Longevity?

Proper installation and proactive maintenance maximize service life and minimize unplanned shutdowns. Adhering to best practices preserves seal integrity and simplifies troubleshooting in harsh conditions.

- Use calibrated torque wrenches matched to fitting size and grade.

- Ensure tubing ends are cut square with burr-free surfaces.

- Hand-start nuts before final torque to align ferrule and body.

- Conduct periodic inspections for torque loss, corrosion, and tubing movement.

Following these steps prevents installation errors, reduces leak incidence, and extends fitting lifespan, even under heavy vibration or thermal cycling.

What Are the Best Practices for Proper Installation?

Align tubing in fitting body, hand-thread the nut until finger-tight, then apply manufacturer-specified torque in one smooth motion. Avoid re-seating the fitting after initial compression to preserve ferrule geometry and sealing performance.

How Can Common Issues Be Troubleshed and Prevented?

Leak detection begins with visual inspection for drips or seepage, followed by bubble-testing under low pressure. Misaligned ferrules can be corrected by disassembly, cleaning, and re-torquing to spec. Regular checks for loose nuts and corrosion spots avert unplanned downtime.

What Maintenance Schedules Maximize Fitting Lifespan in Harsh Conditions?

Inspect fittings every 3–6 months in corrosive or vibration-intense environments, tightening nuts to nominal torque as needed. Replace ferrules and nuts upon any sign of deformation or pitting to sustain leak-proof performance over years of service.

How Do Stainless Steel Compression Fittings Compare to Other Connection Types?

Stainless steel compression fittings offer distinct benefits over welded, brazed, or alternative-material connections, balancing installation ease with performance.

- Flexibility and Speed – No hot work permits or specialized welding skills required.

- Corrosion Resistance – Outperforms copper or carbon steel in aggressive media.

- Serviceability – Enables disassembly and reconfiguration without cutting tubing.

- Safety – Eliminates heat-related hazards and weld defects in critical systems.

These advantages make compression fittings the preferred choice for modular skid assemblies, instrumentation loops, and retrofit projects where downtime and safety are key concerns.

What Are the Advantages Over Welded and Other Material Fittings?

Compression fittings avoid heat-affected zones and weld cracking, reduce installation time by up to 70%, and allow for on-site adjustments. Unlike copper or PEX, stainless steel maintains structural integrity in high-temperature and high-pressure applications without softening or outgassing.

When Should You Choose Stainless Steel Over Alternatives Like Copper or PEX?

Select stainless steel fittings when systems require greater chemical compatibility, tighter leak rates, and higher temperature or pressure ratings. Copper and PEX serve low-pressure or non-corrosive services, but stainless steel is essential for critical process and safety-related piping.

How Do Cost and Sustainability Impact Material Selection?

Though stainless steel fittings carry higher upfront costs, their long service life, recyclability, and reduced maintenance downtime lower total cost of ownership. The alloy’s 100% recyclability aligns with circular-economy goals and green building standards.

How Can You Choose the Right Stainless Steel Compression Fitting for Your Application?

Selecting optimal fittings involves matching grade, configuration, and size to system requirements, leveraging expert support to tailor solutions.

Selection Factor | Attribute | Consideration |

Operating Pressure | PressureRequirement | Choose grade and ferrule style rated above max system pressure |

Media Compatibility | ChemicalExposure | Verify alloy’s resistance to fluids present |

Temperature Extremes | ThermalLimits | Select grade with service range covering min/max temperatures |

Configuration Needs | FittingType | Single-ferrule for instrumentation, double-ferrule for vibration-resistant lines |

Customization and Support | TechnicalServices | Engage expert guidance for special alloys or non-standard configurations |

Consulting with experts ensures selections meet performance and regulatory demands while optimizing inventory and installation efficiency. Contact our experts to specify fittings tailored to your toughest applications.

Stainless steel compression fittings combine metal-to-metal sealing and robust alloy properties to deliver leak-proof connections in the most demanding industrial environments. Their versatile performance across oil & gas platforms, chemical plants, marine systems, and power generation underscores their role as a core fluid-transfer component. By selecting the appropriate stainless steel grade, adhering to torque and installation best practices, and scheduling proactive maintenance, engineering teams secure long-term reliability and safety. Explore ARPC Supply’s history of innovation and commitment to quality here.